Extended reading: Hydrostatic Level Measurement The greater the force of liquid, the greater the volume of fluid. Submersible level sensor, Pressure and DP level transmitter are all hydrostatic measurement devices.Īlso known as pressure level transmitters, these transmitters help in determining fluid contents of a container, by measuring the pressure of the resting body of the fluid within it. Read more about: Ultrasonic Tank Level Sensor-External Mounted

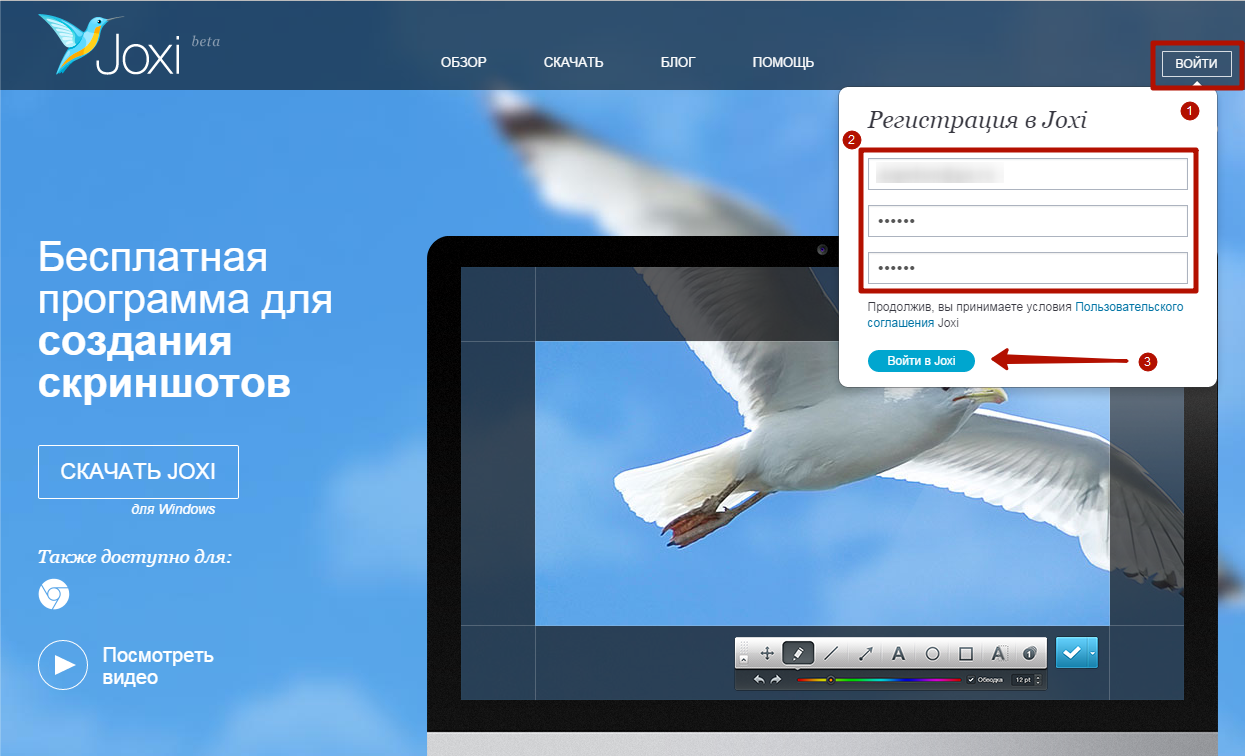

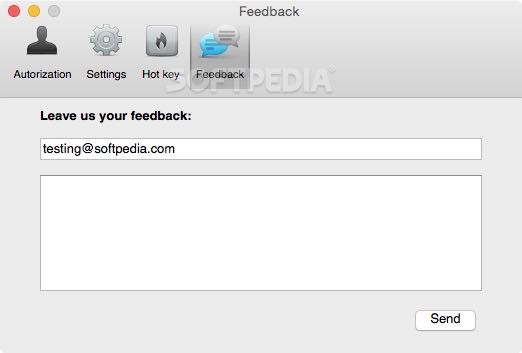

JOXI ENGLISH INSTALL

Easy to install at the top of the tank into standard fittings.Non-contact – nothing touches the liquid.The nature of ultrasonic level measurement is such that levels can be sensed and displayed in real-time.įeatures of Ultrasonic Tank Level Sensor: While float switches and other sensors are adept at measuring when liquid levels are above or below a certain point. Ultrasonic level sensors are also ideal for continuous level measurement. Ultrasonic sensors are ideal for difficult or corrosive liquids such as acids, wastewater, and others.

Ultrasonic sensors work without the need to touch the medium being measured. The speed of sound (340 m/s in air at 15 degrees C, 1115 fps at 60 degrees F) depends on the mixture of gases in the headspace and their temperature. These sensors use frequencies in the tens of kilohertz range transit times are ~6 ms/m. Using the time required for an ultrasound pulse to travel from a transducer to the fluid surface and back (TOF). Ultrasonic level sensors measure the distance between the transducer and the surface. Ultrasonic level sensor measure continuous liquid level, fluid level, or oil level. Ultrasonic fuel tank level sensor, also called non-contact fuel meter.

0 kommentar(er)

0 kommentar(er)